close

Choose Your Site

Global

Social Media

| Availability: | |

|---|---|

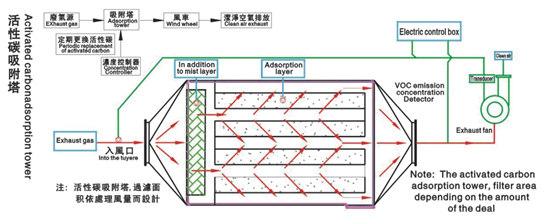

It uses high-efficiency activated carbon to adsorb VOCs and a thermal or steam desorption process to regenerate the carbon, allowing for repeated use and reducing operational costs.

This system is ideal for industries with low to medium VOC concentrations and large air volumes, providing both environmental compliance and economic value by enabling solvent recovery.

|  |

Dual-function system: adsorption + desorption (regeneration)

Suitable for benzene, toluene, xylene, acetone, ethanol, etc.

Activated carbon can be regenerated via hot air or steam

Optional solvent recovery tank for energy and material recycling

PLC control system for safe and automated operation

Long service life, high removal efficiency, low running cost

Coating and painting workshops

Pharmaceutical and chemical factories

Packaging and printing facilities

Petrochemical VOC treatment

Electronic manufacturing exhaust gas purification

Model | Outline size | Ventilation cross-sectional area m ² | Carbon loading m ³ | Air volume |

YLHXT-0.5 | 1600*1200*1800 | 1.92 | 0.38 | 5000 |

YLHXT-0.8 | 1800*1200*1800 | 2.4 | 0.48 | 8000 |

YLHXT-1 | 2000*1300*1800 | 2.88 | 0.58 | 10000 |

YLHXT-1.5 | 2300*1300*1800 | 3.6 | 0.72 | 15000 |

YLHXT-2 | 2600*1500*1800 | 4.3 | 0.86 | 20000 |

YLHXT-3 | 3000*1500*1800 | 5.3 | 1.06 | 30000 |

YLHXT-4 | 3600*1700*1800 | 6.72 | 1.34 | 40000 |

YLHXT-5 | 4000*1700*1900 | 8.32 | 1.66 | 50000 |

YLHXT-6 | 4600*2000*1900 | 9.88 | 1.98 | 60000 |

YLHXT-7 | 5000*2000*2000 | 11.76 | 2.35 | 70000 |

YLHXT-8 | 5000*2200*2200 | 13.44 | 2.69 | 80000 |

YLHXT-9 | 5500*2200*2200 | 15.04 | 3 | 90000 |

YLHXT-10 | 6000*2200*2200 | 16.64 | 3.33 | 100000 |