close

Choose Your Site

Global

Social Media

| Availability: | |

|---|---|

Place Of Origin: | CHINA |

Processing Capacity: | 1200~30000 M3/H |

Supply Ability: | 50 Sets Per 3 Months |

Material: | PP/FRP |

Purifying Rate: | >90% |

Packaging Details: | Pallets |

Highlight: | Purification Tower 30000 M3/H |

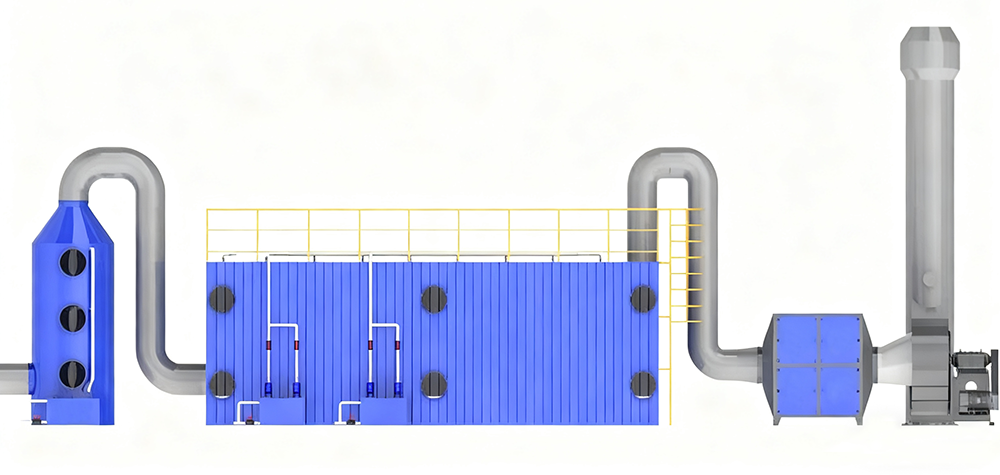

The biological deodorization tower utilizes microorganisms growing on the packing material to decompose odorous substances in exhaust gases through metabolic processes.

Odorous gases flow through the moist packing layer inside the tower, where they are captured by the packing and absorbed by microorganisms attached to it. These microorganisms then break down the pollutants into harmless substances such as water, carbon dioxide, and sulfates.

Pre-treatment and Humidification: The odorous exhaust gas is sent into the tower by a fan and humidified to provide sufficient moisture, which promotes microbial growth and activity.

Gas Introduction: The humidified gas enters the bio-trickling filter or biofilter and comes into contact with the packing material.

Microbial Absorption: The microorganisms attached to the packing material absorb and capture pollutants in the exhaust gas.

Biodegradation: Microorganisms use pollutants as sources of energy and carbon, decomposing them into harmless and stable inorganic substances such as water, carbon dioxide, and sulfates through metabolic activities.

Gas Discharge: The purified gas is finally discharged from the tower and typically meets environmental emission standards.

Environmentally Friendly: The biological treatment process produces almost no secondary pollution.

Low Operating Cost: Compared to traditional physical and chemical methods, it has lower energy consumption and operating costs.

High Efficiency: Treatment efficiency typically exceeds 90%.